We’re hosting a free tech demo on February 7.

#Ultimaker cura 4.7 manual pdf 1080p

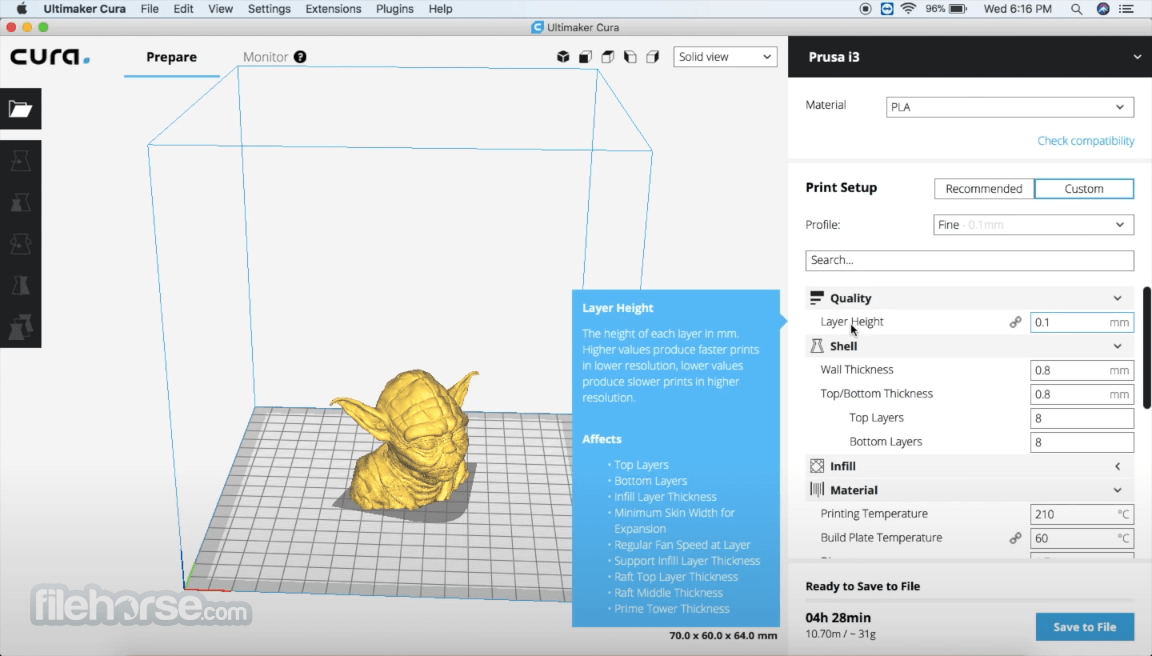

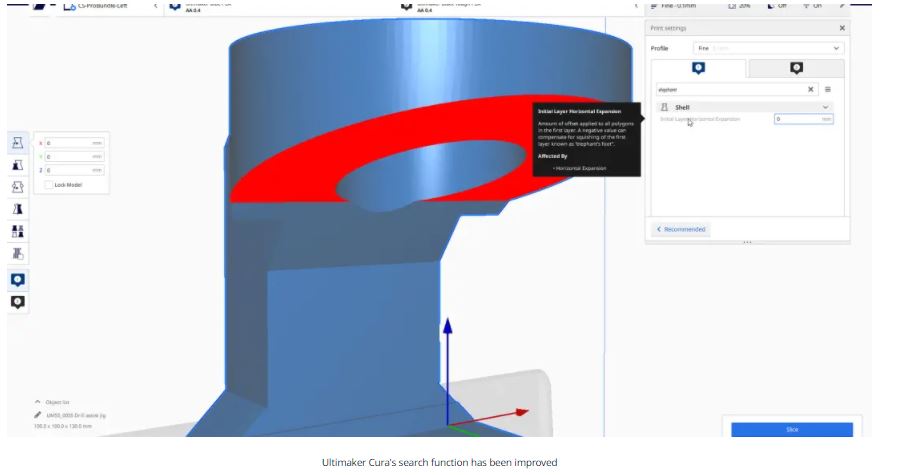

Reliable bed tilt compensation (no more thumbscrews) 2.4 and 5 GHz Wi-Fi A 1080p camera (mounted higher for a better view) Compatibility with 280+ Marketplace materials Compatibility with S5 project files (no reslicing needed) And a whole lot more The UltiMaker S7 also includes quality of life improvements: We also reversed the front fan direction (fewer plastic hairs, less maintenance), made the print core door magnets stronger, and add a sensor that helps avoid flooding. Cura 4.7.1 by Ultimaker Publication date 2020-09 Topics 3D printer slicing application Language Multiple Ultimaker Cura is a state-of-the-art slicer application to prepare your 3D models for printing with a 3D printer. This effectively makes it much harder to not achieve a perfect first layer, improving overall print success. The re-engineered print head has an inductive sensor which reduces noise when probing the build plate. 1.3 Apparatus: FDM Creality E-3 machine, 3D model. Along with that, 4 pins and 25 magnets make it easy to replace the flex plate perfectly – even with one hand. 1.2 Objectives: To understand concept of slicing software: Ultimaker cura and 3D printing by FDM process. Settings in Ultimaker Cura 4.7.

#Ultimaker cura 4.7 manual pdf update

But we also don’t recommend using or adhesion structures for UltiMaker materials (except PC, ’s PC). Here we introduce auto and manual two methods to configure the best Cura setting for ET4 Lets get started UPDATE The Ultimaker Cura 4.7.1 setting for Anet ET4, ET4X and ET4 Pro 3D printers is available on the following link. Not only do you not need tools to pop a printed part off. It has been fixed in version 4.7.1, which will likely be released early next week. A PEI-coated flexible steel build plate makes a big difference to productivity. Posted AugUltimaker Cura 4.7 BETA released That’s a bug that happens if you have one or more signs in your start gcode snippet. The build stack has also been completely redesigned. To further enclose the build chamber the S7 only has one magnetically latched door. This filters the exhaust air of every print and also improves build temperature stability. Once finished, the g-code can be sent to the printer for the manufacture of the physical object.

It works by slicing the user’s model file into layers and generating a printer-specific g-code. It now includes an integrated Air Manager. Cura is an open source 3D printer slicing application. The UltiMaker S7 is built on the success of the UltiMaker S5 and its design decisions were heavily based on feedback from customers.

0 kommentar(er)

0 kommentar(er)